Ssop Template

Ssop Template - Use this example as a reference when developing your own establishment’s ssop. These cleaning procedures must be detailed. Each official establishment shall develop, implement, and maintain written standard operating procedures for sanitation (sanitation sops) in accordance with the requirements of this part. A small meat processor must understand the basic principles behind sanitation. A sanitation standard operating procedure (ssop) is a written document of procedures or programs used to maintain equipment and the environment in a sanitary. Sanitation standard operating procedures (ssops) are written procedures or programs used to maintain equipment and the facility environment in a sanitary condition for food processing,. Ssop is a food industry acronym referring to sanitation standard operating procedures. Ssop, or sanitation standard operating procedures, emphasizes the cleaning and sanitization processes to prevent contamination and ensure a safe environment. Proper training of employees is the primary means to reduce food contamination in a processing plant. This document outlines an example sanitation standard operating procedure (ssop) for a meat plant. Proper training of employees is the primary means to reduce food contamination in a processing plant. A small meat processor must understand the basic principles behind sanitation. Use this example as a reference when developing your own establishment’s ssop. These cleaning procedures must be detailed. Ssop is a food industry acronym referring to sanitation standard operating procedures. The ssop’s are implemented throughout a food plant to prevent contamination or. Sanitation standard operating procedures (ssops) are detailed procedures specifying what to clean, how to clean, how frequently to clean, and what records to use for. Ssop, or sanitation standard operating procedures, emphasizes the cleaning and sanitization processes to prevent contamination and ensure a safe environment. This document outlines an example sanitation standard operating procedure (ssop) for a meat plant. Each official establishment shall develop, implement, and maintain written standard operating procedures for sanitation (sanitation sops) in accordance with the requirements of this part. Each official establishment shall develop, implement, and maintain written standard operating procedures for sanitation (sanitation sops) in accordance with the requirements of this part. Sanitation standard operating procedures (ssops) are detailed procedures specifying what to clean, how to clean, how frequently to clean, and what records to use for. Proper training of employees is the primary means to reduce food. Proper training of employees is the primary means to reduce food contamination in a processing plant. A small meat processor must understand the basic principles behind sanitation. The ssop’s are implemented throughout a food plant to prevent contamination or. Sanitation standard operating procedures (ssops) are detailed procedures specifying what to clean, how to clean, how frequently to clean, and what. Proper training of employees is the primary means to reduce food contamination in a processing plant. A sanitation standard operating procedure (ssop) is a written document of procedures or programs used to maintain equipment and the environment in a sanitary. This document outlines an example sanitation standard operating procedure (ssop) for a meat plant. Ssop is a food industry acronym. Ssop, or sanitation standard operating procedures, emphasizes the cleaning and sanitization processes to prevent contamination and ensure a safe environment. A small meat processor must understand the basic principles behind sanitation. These cleaning procedures must be detailed. Proper training of employees is the primary means to reduce food contamination in a processing plant. The ssop’s are implemented throughout a food. Sanitation standard operating procedures (ssops) are written procedures or programs used to maintain equipment and the facility environment in a sanitary condition for food processing,. The ssop’s are implemented throughout a food plant to prevent contamination or. This document outlines an example sanitation standard operating procedure (ssop) for a meat plant. Ssop is a food industry acronym referring to sanitation. A small meat processor must understand the basic principles behind sanitation. Sanitation standard operating procedures (ssops) are written procedures or programs used to maintain equipment and the facility environment in a sanitary condition for food processing,. Use this example as a reference when developing your own establishment’s ssop. Each official establishment shall develop, implement, and maintain written standard operating procedures. Proper training of employees is the primary means to reduce food contamination in a processing plant. A small meat processor must understand the basic principles behind sanitation. A sanitation standard operating procedure (ssop) is a written document of procedures or programs used to maintain equipment and the environment in a sanitary. This document outlines an example sanitation standard operating procedure. Ssop, or sanitation standard operating procedures, emphasizes the cleaning and sanitization processes to prevent contamination and ensure a safe environment. Each official establishment shall develop, implement, and maintain written standard operating procedures for sanitation (sanitation sops) in accordance with the requirements of this part. The ssop’s are implemented throughout a food plant to prevent contamination or. A sanitation standard operating. A small meat processor must understand the basic principles behind sanitation. Use this example as a reference when developing your own establishment’s ssop. Ssop, or sanitation standard operating procedures, emphasizes the cleaning and sanitization processes to prevent contamination and ensure a safe environment. The ssop’s are implemented throughout a food plant to prevent contamination or. Sanitation standard operating procedures (ssops). A small meat processor must understand the basic principles behind sanitation. Each official establishment shall develop, implement, and maintain written standard operating procedures for sanitation (sanitation sops) in accordance with the requirements of this part. Use this example as a reference when developing your own establishment’s ssop. Ssop, or sanitation standard operating procedures, emphasizes the cleaning and sanitization processes to. Ssop, or sanitation standard operating procedures, emphasizes the cleaning and sanitization processes to prevent contamination and ensure a safe environment. A sanitation standard operating procedure (ssop) is a written document of procedures or programs used to maintain equipment and the environment in a sanitary. The ssop’s are implemented throughout a food plant to prevent contamination or. Ssop is a food industry acronym referring to sanitation standard operating procedures. Each official establishment shall develop, implement, and maintain written standard operating procedures for sanitation (sanitation sops) in accordance with the requirements of this part. A small meat processor must understand the basic principles behind sanitation. Sanitation standard operating procedures (ssops) are detailed procedures specifying what to clean, how to clean, how frequently to clean, and what records to use for. These cleaning procedures must be detailed. Sanitation standard operating procedures (ssops) are written procedures or programs used to maintain equipment and the facility environment in a sanitary condition for food processing,.Sop project management template bikiniloki

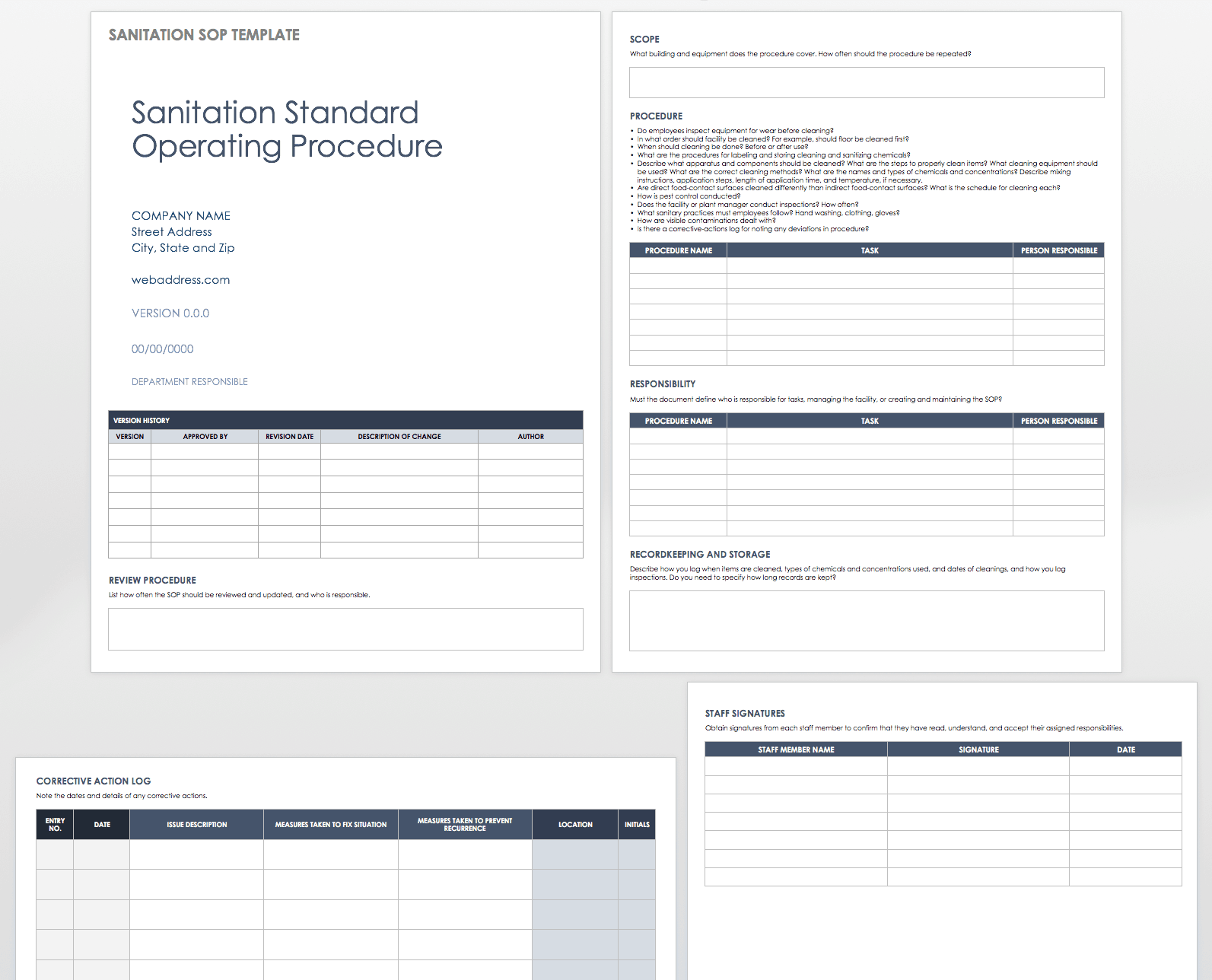

Sanitation Standard Operating Procedures (SSOP) Free Template

Sanitation Standard Operating Procedures SSOP Template Free Download

Standard Operating Procedure Excel Template prntbl

Free Printable SOPs Templates [Word, Excel, PDF] Examples

FORM CHECKLIST SSOP PDF

Sanitation Standard Operating Procedures SSOP Template Free Download

7 Free SOP Templates Learn to Use Them & Create Your Own

Sanitation Standard Operating Procedures SSOP Template Free Download

SSOP Template PDF

This Document Outlines An Example Sanitation Standard Operating Procedure (Ssop) For A Meat Plant.

Proper Training Of Employees Is The Primary Means To Reduce Food Contamination In A Processing Plant.

Use This Example As A Reference When Developing Your Own Establishment’s Ssop.

Related Post:

-1.jpg?quality=low&width=965&height=1350&name=FoodDocs - Sanitation Standard Operating Procedures (SSOP)-1.jpg)

![Free Printable SOPs Templates [Word, Excel, PDF] Examples](https://www.typecalendar.com/wp-content/uploads/2023/05/sop-document-template.jpg?gid=478)

-1.jpg?quality=low&width=1286&height=1800&name=FoodDocs - Sanitation Standard Operating Procedures (SSOP)-1.jpg)

-1.jpg?quality=low&width=1929&height=2700&name=FoodDocs - Sanitation Standard Operating Procedures (SSOP)-1.jpg)